The Role of Hot-Melt Adhesives in Sustainable Single-Use Products

“There must be a better way to make the things we want, a way that doesn’t spoil the sky, or the rain, or the land.” —Paul McCartney

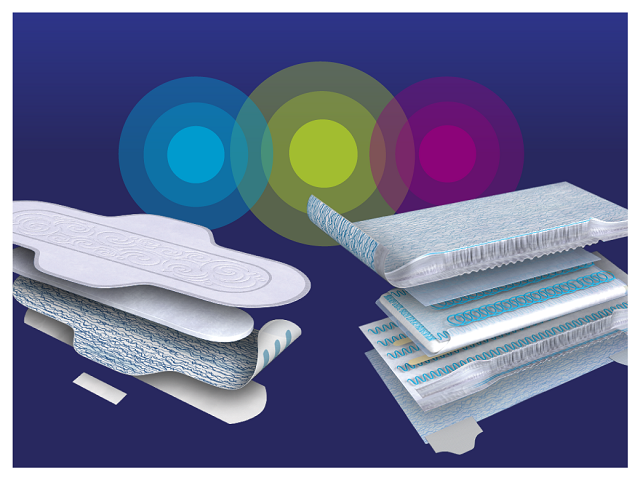

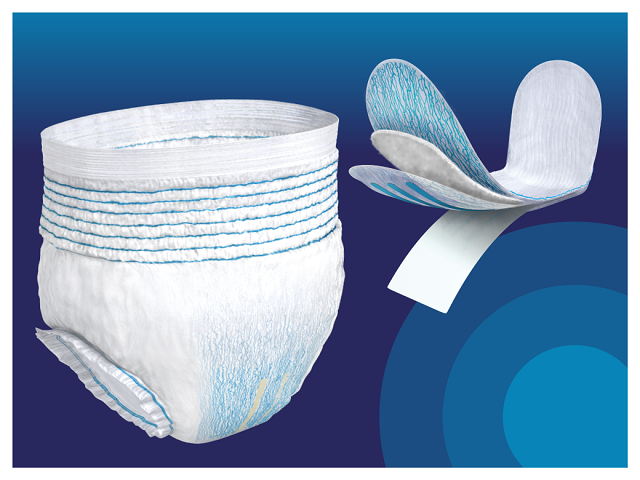

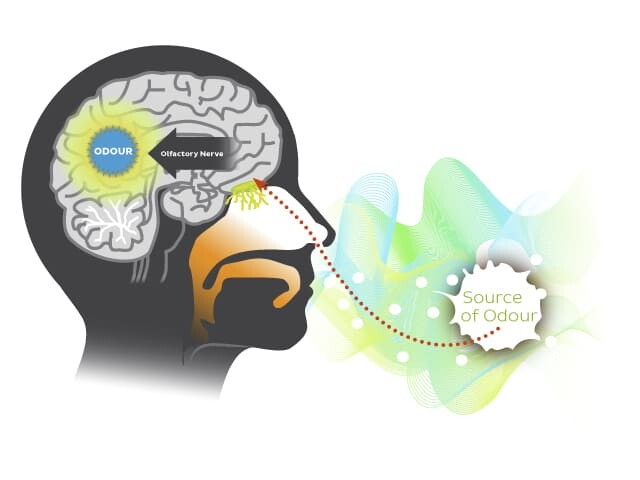

Disposable hygiene products are popular in today’s society because they help to improve quality of life in many ways. Convenience for parents with infants. Confidence for feminine hygiene users at school and work, and during other activities. Security for incontinent adults with busy lives. So, as our collective attention turns to sustainability, we can easily see benefits to society and economy, two of its three pillars.

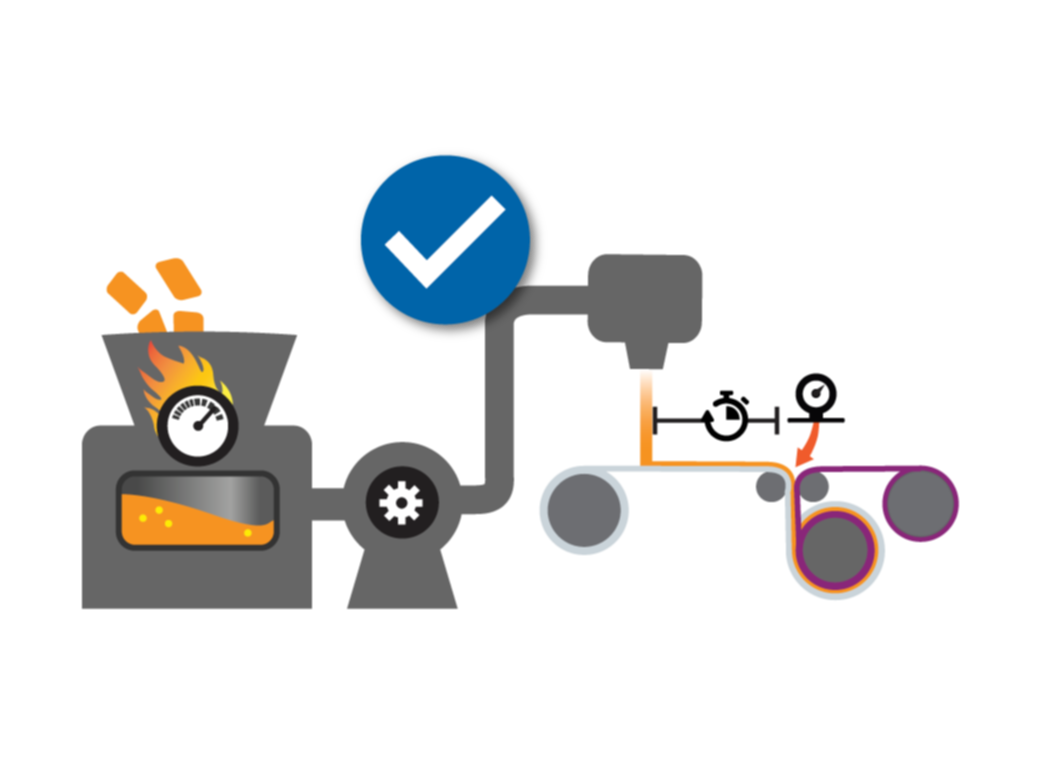

But what about the third pillar, environment? Here, exciting opportunities for improvement present themselves. To minimise disposable hygiene’s negative impacts on the environment, we at Bostik begin by questioning and considering every angle. Although it may surprise some, one way to further this objective is through the use of hot-melt adhesives.

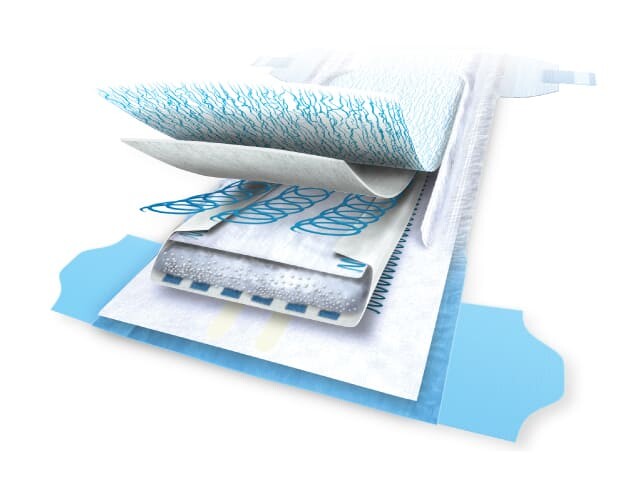

The presence of adhesives in hygiene articles is not typically recognised by consumers of disposable hygiene products. Except for when attaching a pad to the wearer’s underwear or perhaps when closing a diaper, the adhesive generally goes unnoticed. They are not a large part of the product. In fact, adhesives make up only 2-3% of the average diaper by weight. In terms of CO2 emissions, 6% is one estimate1. But they have several critical tasks, from maintaining the integrity of the diaper, to holding elastics firmly in place, to ensuring the performance of the product’s absorbent core.

Adhesives enable sustainability and a more circular economy

Reduce. Reuse. Recycle. These are important concepts in addressing environmental impact. Achieve zero waste, and you have a truly circular system; everything is put back into the economy. Shifting to the use of fewer and renewable resources also contributes to product sustainability. Hot-melt adhesives should support the use of:

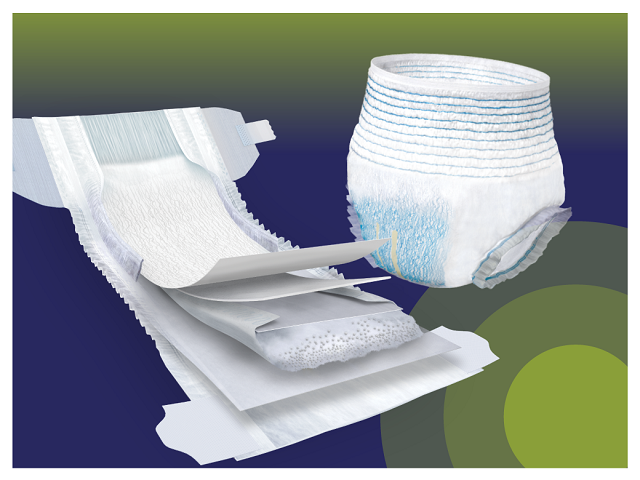

- Bio-based fibres such as cotton and bamboo that reduce dependency on fossil resources

- Thinner substrates, which use fewer raw materials

- Non-traditional core designs, which can reduce the number and weight of materials used

- Bio-based polymer substrates such as PLA that reduce the product’s carbon footprint

In addition, adhesives can help promote a more circular economy through facilitating better end-of-life outcomes such as recycling or composting. We believe they may also allow de-bonding of those substrates for recycling or composting.

In short, hot-melt adhesives offer considerable advantages, especially as an enabler of eco-design. One might consider it rather impressive, for a product that makes up no more than 3% of a disposable diaper by weight.

A better way to make sustainable disposable hygiene possible

At Bostik, we work tirelessly to find better ways to make the disposable hygiene products that your consumers have come to rely upon. Our goal, as always, is to open the door for achieving your manufacturing goals and ambitions for products, consumers, and sustainability.

1Cordella et al, Journal of Cleaner Production 95 (2015) 322-331, table 4.

CSR and Sustainability Materials from Bostik Academy

Click the links below to sign-in and access all of our Academy materials.